Dual hearth smelting furnace (side-blown and top blown Dual hearth smelting furnace)

Integrates all the current crude copper blowing process and equipment technical advantages, and has a number of core technological innovations. A pyrometallurgical copper smelting system with a production capacity of 400000 tons/year can be built by using a smelting furnace to produce matte copper and a continuous blowing furnace to produce blister copper and a rotary anode furnace to refine and produce anode plate copper. The production system consists of a 70 ㎡ melting furnace, a 120 ㎡ blowing furnace, two rotary anode furnaces and a set of double disc casting machines.

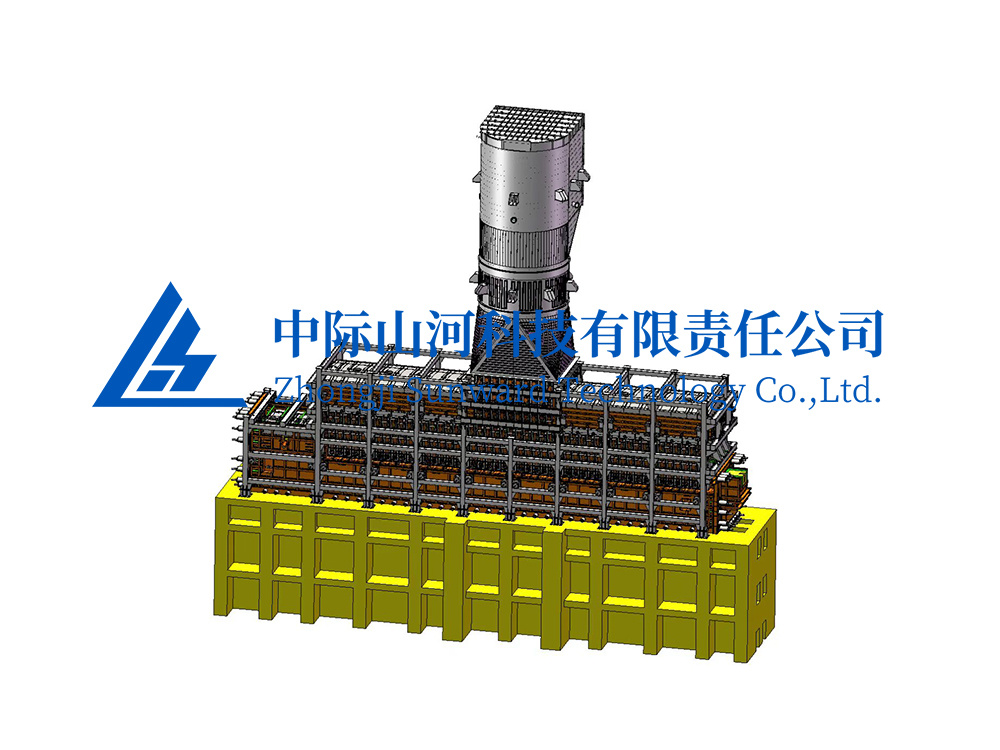

Multi-stage (multi-chamber) roasting furnace

The multi-stage baking furnace that can adapt to multi-nature materials is composed of a furnace body, a driving device, a central shaft, a furnace rake, a temperature control system, etc. It can continuously roast materials at a maximum of 1000 ℃, can accurately control the roasting time and temperature of materials, and can adapt to the roasting of cementitious materials. It can be used in mineral roasting (such as zinc oxide defluorination rate in lead smelting production, etc.), activated carbon regeneration, sludge pyrolysis, wastewater treatment, food sugar adsorption decolorization refining and other fields.

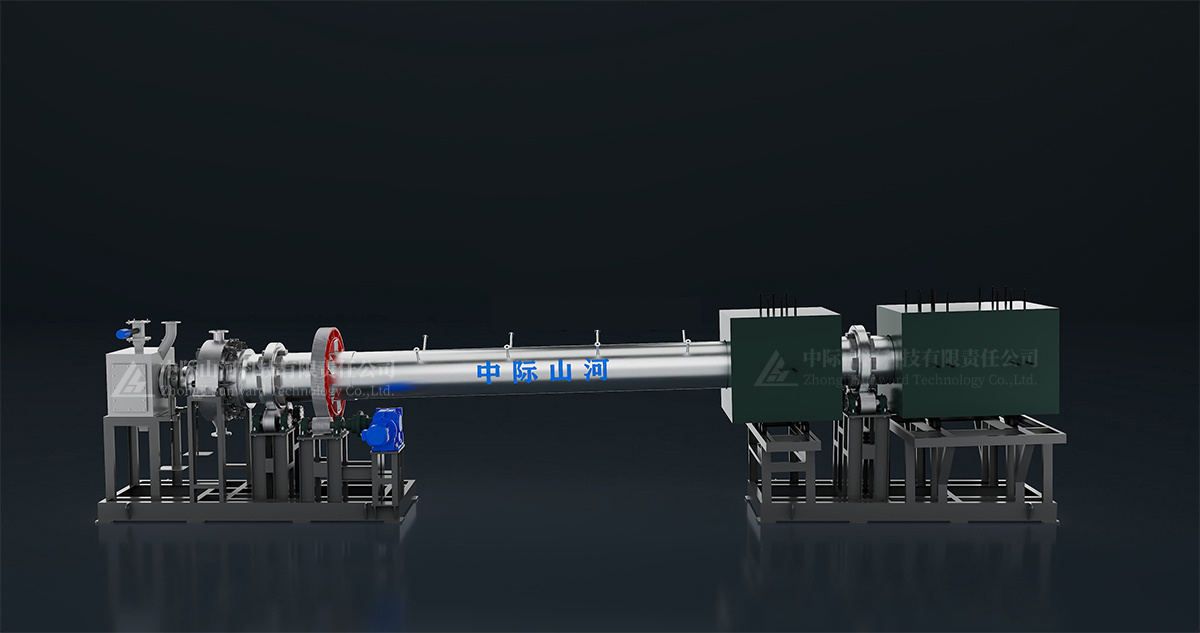

Energy-saving rotary kiln is a heavy-duty equipment that utilizes high-temperature treatment to achieve physical or chemical changes in materials of different compositions, which has different processing methods and processing temperatures such as volatile calcination, calcination, and drying to obtain corresponding results. Most common rotary kilns are used to process non-metallic materials, which are commonly found in building materials such as cement kilns. Some Furance is used for calcining limestone with oxidation reactions. In addition to temperature requirements, metallurgical kilns also emphasize the atmosphere factor inside the kiln based on the material processing process, which can be divided into oxidation reaction, reduction reaction (or chlorination reaction). The processing temperature ranges from 500 to 1300 ℃, and the operating conditions are more stringent and the process is stronger than cement kilns. Rotary kilns choose different kiln body structures based on different heat sources. For reduction reaction rotary kilns, due to strict atmosphere requirements, apart from differences in equipment on the kiln body, the sealing effect of the kiln head and tail is more important. The new energy-saving rotary kiln developed by our company breaks through the shortcomings of extensive and high energy consumption of traditional rotary kilns. It can save more than 50% of energy compared with conventional rotary kilns, helping enterprises significantly reduce production and operation costs.