Copper smelting plate transfer and intelligent storage system

With the continuous development of production enterprises, new demands have been put forward for various logistics links, which also promote the development of production logistics in the direction of intelligence. Our company can customize the design and production of intelligent logistics and warehousing systems for smelting enterprises to help enterprises build intelligent green factories.

Keywords: production equipment selection, system manufacturing, upgrading

Classification:

Smelting equipment

messages

Product Description

Product Introduction:

With the continuous development of production enterprises, new demands have been put forward for various logistics links, which also promote the development of production logistics in the direction of intelligence. Our company can customize the design and production of intelligent logistics and warehousing systems for smelting enterprises to help enterprises build intelligent green factories.

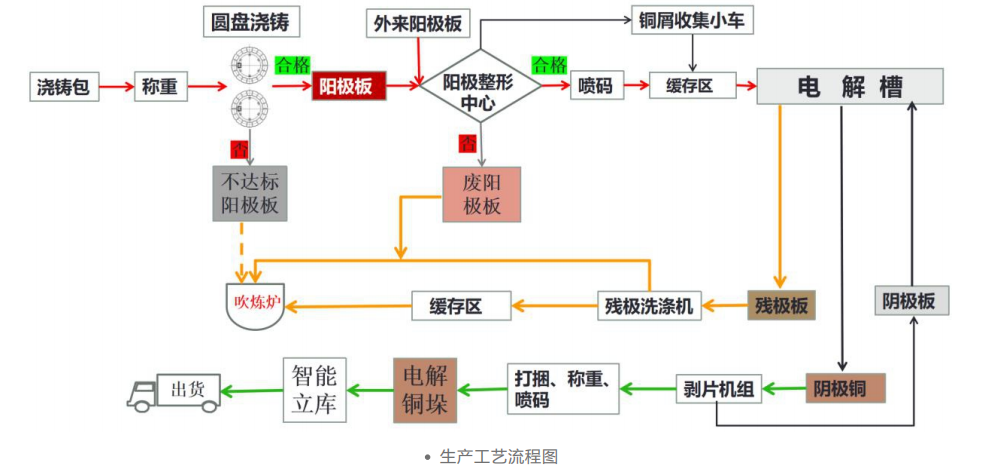

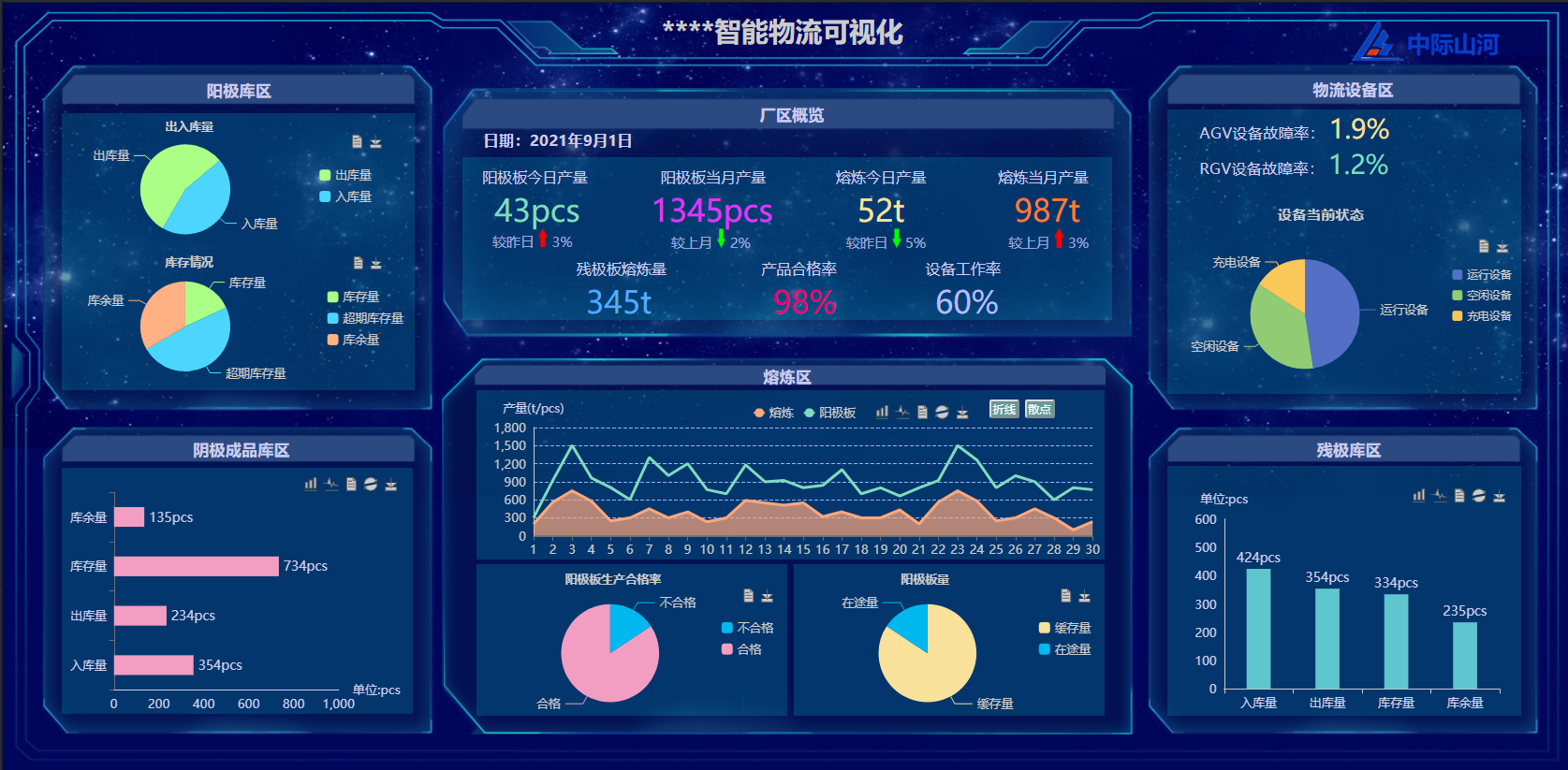

Taking a copper smelting 700000 t/a electrolytic copper plate transfer and intelligent storage system independently developed by our company as an example, the system provides a complete set of merger automation and digital intelligent logistics solutions from disc casting machine smelting workshop → anode shaping unit → anode warehouse-> electrolysis workshop → finished copper warehouse-→ warehouse-out transportation.

Equipment list (taking the plate transfer and intelligent storage system of a copper smelting enterprise as an example)

| Serial Number | Equipment Name | Specifications | Unit | Quantity |

| 1 | Outdoor Heavy Duty AGV | 30t | Taiwan | 8 |

| 2 | Copper chip collection RGV | 1t | Taiwan | 3 |

| 3 | Anode transshipment RGV | 5t | Taiwan | 9 |

| 4 | RGV | 3t | Taiwan | 4 |

| 5 | Plate transfer unit | 5t | Sleeve | 17 |

| 6 | Cross-RGV | 3t | Taiwan | 7 |

| 7 | Cache intelligent driving | 10t | Sleeve | 2 |

| 8 |

Chain conveyor (plate)

|

Sleeve | 9 | |

| 9 | vertical hoist | 5t | Sleeve | 6 |

| 10 | Conveyor (copper stack) |

Group

|

2 | |

| 11 | roller transplanter | 3t | Taiwan | 8 |

| 12 | Copper Stack Transfer RGV | 3t | Taiwan | 4 |

| 13 | Intelligent Library | 1792 Holder | Sleeve | 1 |

| 14 | bridge type transfer machine | 6t | Taiwan | 4 |

| 15 | anode shaping unit | 450 tablets/h | Sleeve | 2 |

| 16 | Residual pole feeding unit | 600 tablets/h | Sleeve | 1 |

Previous Page

Next Page

Previous Page

Next Page

Related Product Recommendation

Exhaust gas scrubbing equipment

Electrolysis multi functional automatic overhead crane

Automatic zinc stripping machine

online message