Residual pole transfer unit English Russian test

The residual pole transfer unit is equipped with the acceptance, storage, transfer and output of the residual anode plate to the residual pole transport vehicle. The unit is mainly composed of No.1 transfer trolley, residual pole pile receiving plate rack, temporary storage rack, No.2 transfer trolley, transfer rail rack and electrical system.

The residual pole transfer unit is equipped with the acceptance, storage, transfer and output of the residual anode plate to the residual pole transport vehicle. The unit is mainly composed of No.1 transfer trolley, residual pole pile receiving plate rack, temporary storage rack, No.2 transfer trolley, transfer rail rack and electrical system.

Copper smelting plate transfer and intelligent storage system

With the continuous development of production enterprises, new demands have been put forward for various logistics links, which also promote the development of production logistics in the direction of intelligence. Our company can customize the design and production of intelligent logistics and warehousing systems for smelting enterprises to help enterprises build intelligent green factories.

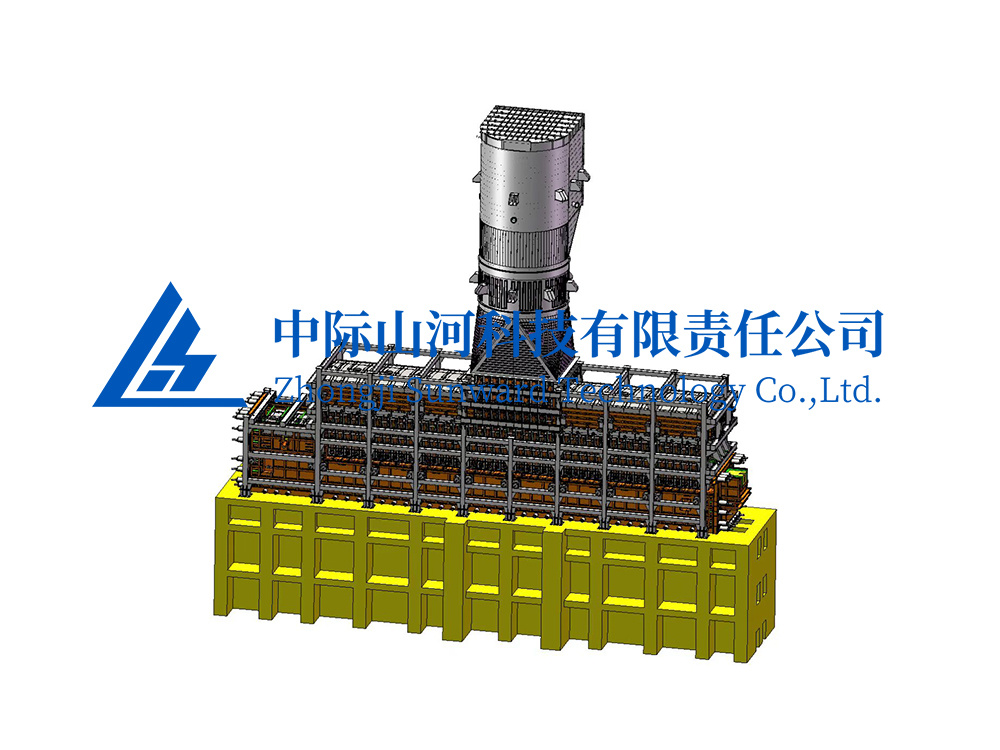

Copper smelting process and equipment with double melting pool

The double-bath copper smelting process and equipment jointly developed and produced by our company and Changsha Nonferrous Metallurgical Design and Research Institute Co., Ltd. integrates all the current crude copper blowing process and equipment technical advantages, and has a number of core technological innovations. A pyrometallurgical copper smelting system with a production capacity of 400000 tons/year can be built by using a smelting furnace to produce crystal copper and a continuous blowing furnace to produce crude copper and a rotary anode furnace to refine and produce anode plate copper. The production system consists of a 70 ㎡ melting furnace, a 120 ㎡ blowing furnace, two rotary anode furnaces and a set of double disc casting machines.

The automatic zinc stripping unit is used to transfer the cathode plate. A complete set of special equipment for stripping, receiving, conveying, palletizing and weighing the zinc sheet, and washing the cathode plate mother plate at the same time.

Hot consolidation material crusher

The thermal consolidation material crusher is a kind of whole grain equipment developed by our company for crushing the thermal consolidation material (such as smoke and dust block) generated by the waste heat boiler. It adopts secondary roller crushing and has a crushing capacity of up to 30 t/h. The product has the characteristics of high strength and wear resistance of crushing teeth, external bearing seat, hollow water cooling of moving tooth roller, reliable dynamic sealing, automatic lubrication and multiple protection, especially suitable for crushing high temperature and high grinding and cutting materials.

The zinc electrowinning anode plate (3.2 ㎡) automatic production line is mainly used to produce qualified anode plates in the zinc electrowinning workshop. It consists of induction furnace, robot feeding device, casting equipment, casting machine, shearing equipment, punching equipment, whole yard conveyor and control system.

Complete set of zinc melting and casting equipment

The complete set of zinc melting and casting equipment developed and produced by our company can realize automatic production of the whole process from palletizing zinc cathode sheets to zinc ingots without landing. It mainly includes zinc cathode sheet conveying line, feeding device, zinc melting induction furnace, ingot casting unit and palletizing unit. At present, the complete set of zinc melting and casting equipment developed and produced by our company in a Guangxi smelter has realized the world's largest annual production capacity of a single production line.