The smarter the factory, the more "relaxed" the workers"

Release time:

2023-11-07 00:00

Source:

Zhongji Sunward Technology Co., Ltd., a subsidiary of Changsha Nonferrous Institute, aims to realize the intelligence, precision and greening of the non-ferrous metal beneficiation and smelting industry, and carry out the research and development, design and manufacture of process supporting high-tech equipment and its control automation. Breakthroughs have been made in the fields of zinc, lead, copper smelting, furnaces, and new energy. These innovative technologies and high-end automation equipment are widely used in a series of major mining smelting projects and overseas high-quality projects across the country, which greatly reduces the labor intensity of workers in factories and mining enterprises, significantly improves work efficiency, and effectively guarantees that the majority of workers in factories and mining enterprises are in good spirits. The state is put into safe production.

● Application of Full Automatic Zinc Stripping Equipment

The complete set of full-automatic zinc stripping equipment is mainly composed of full-automatic multi-functional insulation driving, full-automatic zinc stripping washing unit and full-automatic anode chain beating unit. It adopts many cutting-edge technologies such as robot load transfer, image recognition, laser and encoder, multi-stage positioning of positioning cone, plate traceability, etc.

The complete set of equipment has been successfully applied to the zinc electrowinning workshop of Guangxi Nandan southern nonferrous metals co., ltd. "zinc oxygen pressure leaching technology innovation green manufacturing project", realizing high-precision automatic positioning of equipment, high-reliability continuous operation and efficient collaborative intelligent management. the production efficiency of a single workshop of zinc electrowinning is the largest in China, which is a major breakthrough in the equipment upgrading of zinc electrowinning workshop in China.

The picture shows the zinc electrowinning workshop of "zinc oxygen pressure leaching technology innovation green manufacturing project" in southern Guangxi. Photo by He Hao

● Application of lead electrolysis complete automation equipment

A full set of automation equipment for lead electrolysis organically integrates process, equipment, environmental protection and other aspects, and realizes the whole process automation of lead electrolysis through intelligent equipment operation and digital process control, which can significantly reduce energy efficiency, increase production capacity, improve indicators and improve economic benefits.

In the "Green Upgrading and Transformation Project of Zinc Slag in Danxia Smelter" of Zhongjin Lingnan Nonferrous Metals Co., Ltd., the equipment has successfully built an intelligent and digital factory through DCS control center to realize the coordinated and automatic operation of intelligent driving, residual pole washing unit, lead precipitation washing unit, yin and yang plate row spacing unit, conveying line, plate transfer rail trolley and other equipment in the same control platform.

The picture shows the lead electrolysis workshop of Zhongjin Lingnan "Green Upgrade Project of Zinc Slag in Danxia Smelter. Photo by Gao Han

● Application of Lead Large Plate Electrolysis Process

The large plate electrolysis process of lead adopts large plate, large electrolytic cell, long period electrolysis, cathode and anode plate production, cathode and anode electrode automatic spacing, lead precipitation automatic rod extraction, residual electrode automatic washing, lead ingot casting, etc. to realize mechanization and automation, which is a great promotion and improvement of electrolysis process technology, and is of great significance to realize large-scale production, improve production efficiency, reduce energy consumption, improve environment and improve resource utilization efficiency.

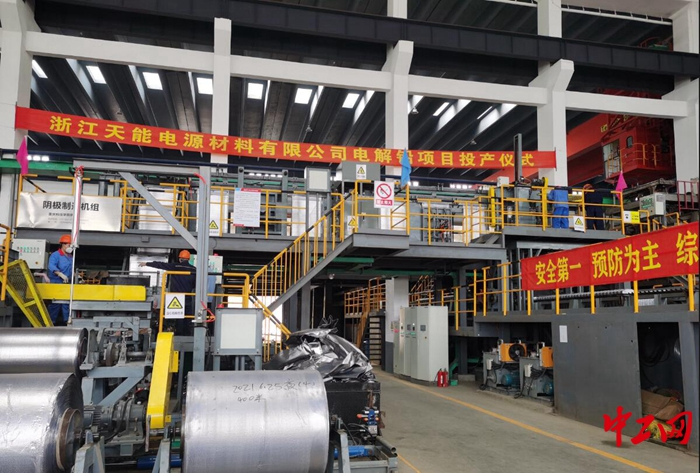

After adopting this process technology, the 120000-ton electrolytic lead project in the third phase of Zhejiang Tianneng Power Supply Materials Co., Ltd. was completed and put into operation in one year. It took only half a month to successfully pull through the production line and officially produce lead precipitation.

Zhejiang Tianneng Phase III 120000 Tons Electrolytic Lead Project was officially put into operation. Photo by Liu Yigao

● Application of nickel production line series equipment

Nickel production line series equipment includes mixing tank, large agitator, cylinder washing machine, etc., in the "green intelligent" mode, the use of world-leading technology, can meet the direct production of new energy nickel chemicals from laterite nickel ore process demand, the global low-grade nickel resources efficient utilization of great significance.

This series of mixing and washing equipment has been successfully applied to the production line of the nickel chemical raw material factory for power battery in Indonesia's Qingmeibang Comprehensive Industrial Park. The nickel oxide intermediate products and high quality battery grade nickel chemicals produced meet the development needs of the global new energy industry, with broad market prospects and obvious economic benefits.

The picture shows a nickel chemical raw material factory for power batteries in Indonesia's

● Qingmeibang Comprehensive Industrial Park. Photo by Liang Haibo

In the future, Zhongji Sunward will continue to provide in-depth services for the vast number of mining and smelting enterprises, and lead enterprises to realize digital and intelligent transformation and green transformation with technological innovation and equipment research and development upgrading, so as to effectively improve the working environment of workers, improve the safety and security of workers, promote the overall improvement of workers' quality, and contribute unique wisdom and strength to further enhance the happiness, sense of achievement and sense of security of workers in factories and mining enterprises. (Liu Jinting)

Previous Page