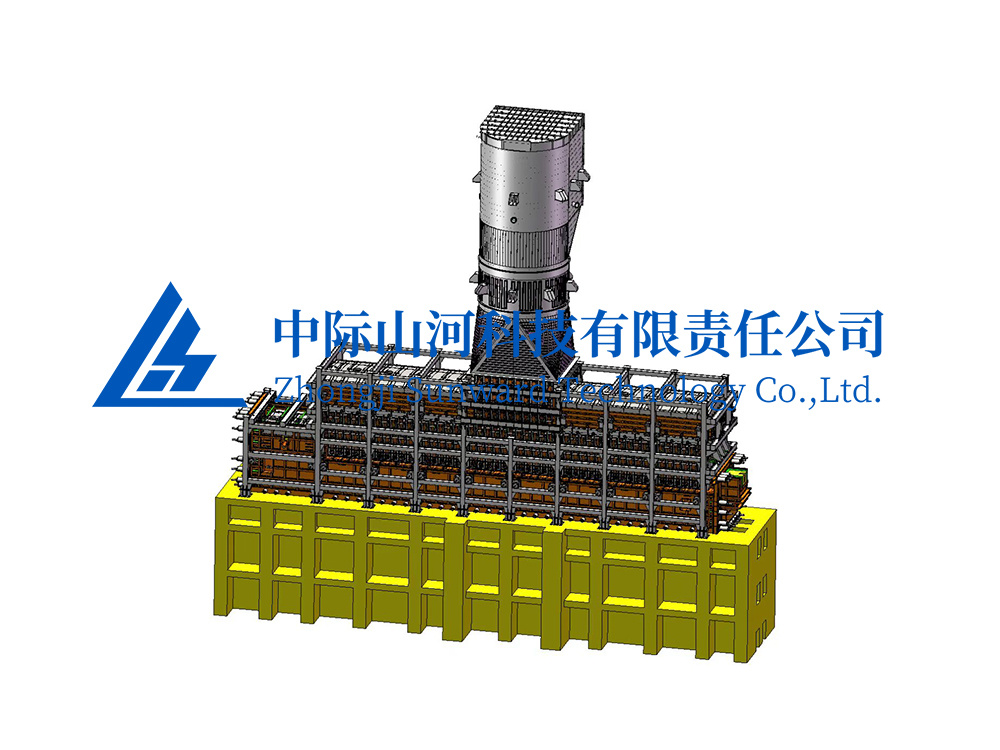

Complete set of zinc melting and casting equipment

The complete set of zinc melting and casting equipment developed and produced by our company can realize automatic production of the whole process from zinc cathode sheet palletizing to zinc ingots without landing. It mainly includes zinc cathode sheet conveying line, feeding device, zinc melting induction furnace, ingot casting unit and palletizing unit. At present, the complete set of zinc melting and casting equipment developed and produced by our company in a Guangxi smelter has achieved a single production line capacity of 175kt/a.

CCF flotation column is a new type of high-efficiency non-mechanical stirring aerated flotation equipment with column tank structure. It uses the flow mode of ore particles and fine bubbles in countercurrent and smooth contact, which provides a large number of opportunities for collecting ore particles. The bubbles in the column are small and uniform, the surface area is large, and there are more opportunities to contact with the ore particles under countercurrent conditions, which eliminates the "short circuit" phenomenon of useful minerals in the flotation process, and is conducive to improving the flotation speed and recovery rate. The thickness of the foam layer in the column is large, adjustable, and the cleaning effect of countercurrent flushing water, so the concentration enrichment ratio is large, which can significantly improve the concentrate grade. CCF flotation column can be used to deal with black, non-ferrous, non-metallic ore, as well as chemical, paper, environmental protection and other industries in the waste residue, waste liquid. In particular, it is applied to the technological transformation and production capacity tapping of old mining enterprises. "Using intelligent control system to adjust the process parameters such as feeding, discharging and liquid level" can achieve "more, faster, better and less".

High efficiency tank mixer &Agitators

The main features of CGJ series mixing equipment: the design adopts low speed, large impeller scheme, and is equipped with deflector and baffle structure design, so that the slurry flow forms a "W" flow direction, so as to achieve low energy consumption, low wear and tear, and effectively extend the overall life of the equipment. The stirring intensity is large, the tank does not sink and the slurry suspension is high. The bottom of the tank body is provided with a guide cone to eliminate the "dead angle" of stirring and avoid particle deposition and stacking. It can be used for stirring high-concentration slurry with ore density ≥ 3.0 t/m and ore slurry concentration of 30-50%. The material (ore slurry) enters the cone barrel from the upper side of the tank body and is preliminarily mixed with the reagent added from the top of the tank top of the tank body, after mixing, the material (pulp) is discharged from the upper overflow port, which can prevent the material from "short circuit" and make the agent fully function on the surface of the material.

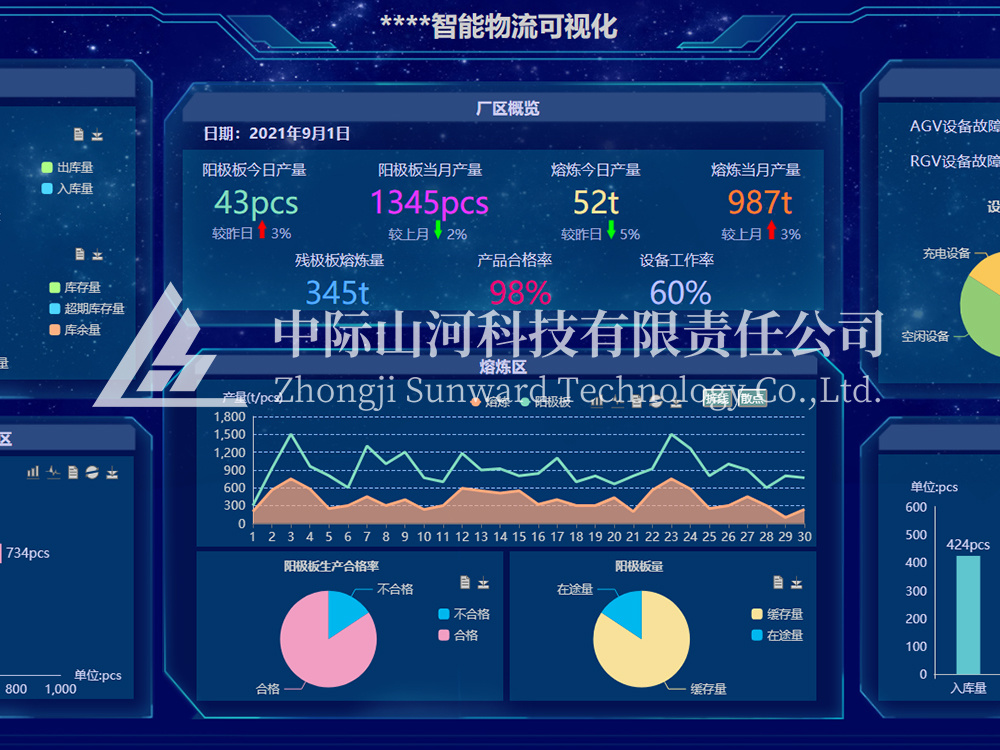

Copper smelting plate transfer and intelligent storage system

With the continuous development of production enterprises, new demands have been put forward for various logistics links, which also promote the development of production logistics in the direction of intelligence. Our company can customize the design and production of intelligent logistics and warehousing systems for smelting enterprises to help enterprises build intelligent green factories.

Dual hearth smelting furnace (side-blown and top blown Dual hearth smelting furnace)

Integrates all the current crude copper blowing process and equipment technical advantages, and has a number of core technological innovations. A pyrometallurgical copper smelting system with a production capacity of 400000 tons/year can be built by using a smelting furnace to produce matte copper and a continuous blowing furnace to produce blister copper and a rotary anode furnace to refine and produce anode plate copper. The production system consists of a 70 ㎡ melting furnace, a 120 ㎡ blowing furnace, two rotary anode furnaces and a set of double disc casting machines.

Multi-stage (multi-chamber) roasting furnace

The multi-stage baking furnace that can adapt to multi-nature materials is composed of a furnace body, a driving device, a central shaft, a furnace rake, a temperature control system, etc. It can continuously roast materials at a maximum of 1000 ℃, can accurately control the roasting time and temperature of materials, and can adapt to the roasting of cementitious materials. It can be used in mineral roasting (such as zinc oxide defluorination rate in lead smelting production, etc.), activated carbon regeneration, sludge pyrolysis, wastewater treatment, food sugar adsorption decolorization refining and other fields.

Lead precipitation conveying line

The lead extraction line is the main equipment of lead smelting (lead electrolysis workshop). Its purpose is to send the lead stack sent by the lead extraction rod washing unit of the lead electrolysis workshop to the electric lead pot for refining through lifting device, chain conveyor and feeding machine, and then send the lead liquid to the linear ingot casting machine for ingot casting or to the cathode casting roll unit for manufacturing lead rolls through the lead pump. The unit is composed of 1# conveyor, vertical rotating hoist, 2# conveyor, 3# conveyor, jacking transfer machine, lifting conveyor, lead pot cover, hydraulic system, electric control system, etc.

The zinc electrowinning anode plate automatic production line mainly produces qualified anode plates for the zinc electrowinning workshop, which is composed of induction furnace, robot feeding device, casting equipment, casting machine, shearing equipment, punching equipment, whole code conveyor and control system.