Southern non-ferrous 300kt/a zinc electrowinning complete set of automation equipment

The complete set of automation equipment for zinc electrowinning is mainly composed of full-automatic multi-functional insulation driving, full-automatic zinc stripping and washing unit, and full-automatic anode chain beating unit. It adopts many cutting-edge technologies such as robot load transfer, image recognition, laser and encoder, multi-stage positioning of positioning cone, plate traceability, etc.

Electrolysis multi functional automatic overhead crane

Electrolysis multi-functional automatic line is the most important core equipment in the electrolysis workshop of non-ferrous metal wet smelting process. It is important to automatically lift the cathode and anode plates from the electrolytic cell and the plate access frame to realize the accurate slot and loading of the cathode and anode plates. Our company is the first enterprise in China and even in the world to successfully develop fully automatic zinc electrowinning and lead electrolysis multi-function automatic driving and successfully realize industrial application.

Automatic zinc stripping machine

The automatic zinc stripping machine is a complete set of special equipment for stripping, receiving, conveying, palletizing and weighing the zinc sheet, and washing the mother plate of cathode plate at the same time.

The trough washing machine is used for the first stage of washing operation to scrub -50mm (or -20mm) materials (including mud) separated from the cylinder washing machine. Its main tasks are two: one is to wipe off the clay (or powder ore) that is larger than 2mm and adheres to the surface of the ore (or gravel); The second is to recover (or discard) suspended materials (clay or powder ore) less than the design requirements (such as-2mm) from overflow to discharge, the lump ore (or gravel) larger than the design requirement (such as 2mm) is separated and recycled (or discarded) by countercurrent.

In order to meet the process requirements, two stage operation is generally used for ore washing. Cylinder washing machine belongs to the first stage of washing operation equipment. The process requires the cylinder washing machine to complete two tasks: one is to separate and discharge -50mm (or-20mm mm) materials into the equipment for the second-stage washing operation as soon as possible; The second is to ensure sufficient flushing time to flush the 50mm (or 20mm) of ore or gravel to achieve the purpose of recovery or exclusion.

Thermosetting materials crusher machine

The thermal consolidation material crusher is a kind of whole grain equipment developed by our company for crushing the thermal consolidation material (such as smoke and dust block) generated by the waste heat boiler. It adopts secondary roller crushing and has a crushing capacity of up to 30 t/h. The product has the characteristics of high strength and wear resistance of crushing teeth, external bearing seat, hollow water cooling of moving tooth roller, reliable dynamic sealing, automatic lubrication and multiple protection, especially suitable for crushing high temperature and high grinding and cutting materials.

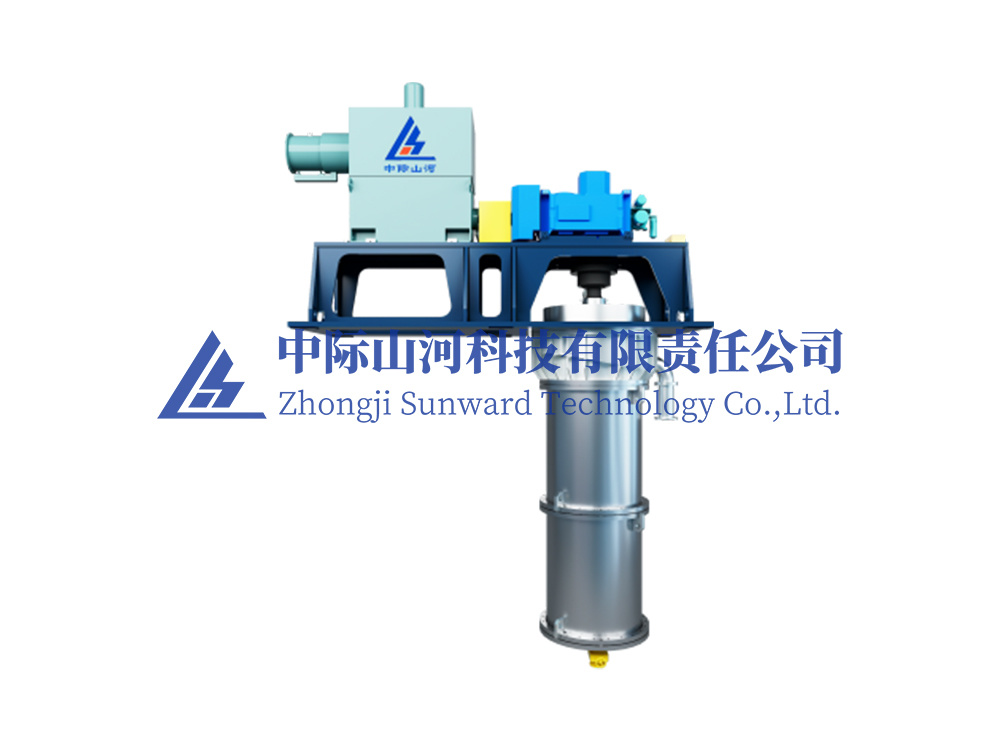

Ultra-fine vertical Grindinng Mill

The ZSM series vertical superfine grinding machine developed by our company is mainly composed of dispersion, grinding and separation systems. For the oxygen pressure leaching process, the metal leaching rate can be significantly improved by using ZSM mill for fine grinding and superfine grinding of metal concentrate slurry. For non-ferrous metal refractory minerals embedded in fine particles, it is an effective way to improve the recovery rate and obtain high quality concentrate by achieving sufficient monomer separation through fine grinding and superfine grinding.

Technical parameters:

Model

ZSM1000

ZSM1500

ZSM2500

ZSM3000

Nominal volume (L)

1000

1500

2500

3000

Power (kW)

400

560

710

800

Dry base handling capacity (t/h)

12

16

19

24

Complete set of zinc melting and casting equipment

The complete set of zinc melting and casting equipment developed and produced by our company can realize automatic production of the whole process from zinc cathode sheet palletizing to zinc ingots without landing. It mainly includes zinc cathode sheet conveying line, feeding device, zinc melting induction furnace, ingot casting unit and palletizing unit. At present, the complete set of zinc melting and casting equipment developed and produced by our company in a Guangxi smelter has achieved a single production line capacity of 175kt/a.