Industrial Furnaces

In the field of nonferrous metallurgical furnaces, Changsha Nonferrous Institute has successfully developed a series of metallurgical furnaces with independent intellectual property rights and core competitiveness, such as lead flash melting furnace, oxygen-enriched side blowing furnace, copper top blowing furnace, fluidized roasting furnace, fuming furnace, continuous refining furnace, multi-stage roasting furnace, continuous blowing furnace, ISF furnace, lead/zinc rain condenser, distillation tower, electric furnace, rotary side blowing furnace, anode furnace, etc. These core technologies and equipment have been widely used in industries and fields such as copper, lead, zinc, tin, nickel, antimony, zinc leaching slag, and copper-containing solid waste. A number of high-quality projects have been built, leading the development of the non-ferrous metallurgical furnace industry and making important contributions to the improvement of equipment technology level in the non-ferrous industry.

Keywords: production equipment selection, system manufacturing, upgrading

Classification:

Engineering case

messages

Product Description

In the field of nonferrous metallurgical furnaces, Changsha Nonferrous Institute has successfully developed a series of metallurgical furnaces with independent intellectual property rights and core competitiveness, such as lead flash melting furnace, oxygen-enriched side blowing furnace, copper top blowing furnace, fluidized roasting furnace, fuming furnace, continuous refining furnace, multi-stage roasting furnace, continuous blowing furnace, ISF furnace, lead/zinc rain condenser, distillation tower, electric furnace, rotary side blowing furnace, anode furnace, etc. These core technologies and equipment have been widely used in industries and fields such as copper, lead, zinc, tin, nickel, antimony, zinc leaching slag, and copper-containing solid waste. A number of high-quality projects have been built, leading the development of the non-ferrous metallurgical furnace industry and making important contributions to the improvement of equipment technology level in the non-ferrous industry.

The metallurgical furnaces of Changsha Institute of Nonferrous Metals have developed for 70 years. Its technology covers all parts of the country, and more than 1,000 nonferrous metallurgical furnaces have been built.

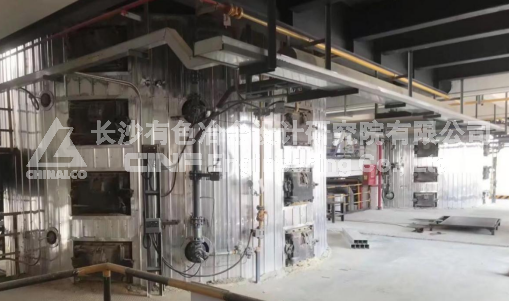

Ultra-large metallurgical furnace equipment developed and designed by Changsha Nonferrous Metals Institute:

★ The world's largest oxygen-enriched side blown furnace for copper smelting (70 ㎡)

★ The world's largest copper smelting top-blown furnace (120 ㎡)

★ The world's largest oxygen-enriched side-blown furnace for zinc smelting slag treatment (45 ㎡)

★ The world's largest fuming furnace (48 ㎡)

★ The world's largest fluidized boiling roaster (198 ㎡)

Metallurgical furnaces of Changsha Nonferrous Metals Institute lead the development of the industry:

★ In 1999, the first oxygen-enriched side blowing furnace test line in China was built

★ In 2002, the first collection of oxygen-enriched side-blown furnace was published in China

★ In 2008, the first 20 ㎡ oxygen-enriched side-blown furnace in China for processing copper and nickel ore was built

★ In 2013, the first oxygen-enriched dual-zone side-blown furnace in China for treating zinc leaching residue was built

★ In 2014, the first 9.5 ㎡ oxygen-enriched side-blown oxidation furnace + 7.5 ㎡ oxygen-enriched side-blown reduction furnace in China for processing lead-based high-arsenic complex materials was built

★ In 2016, the first 26.5 ㎡ oxygen-enriched side-blown oxidation furnace + 21.5 ㎡ oxygen-enriched side-blown reduction furnace + 17 ㎡ oxygen-enriched side-blown fuming furnace for treating brittle sulfur-lead-antimony ore in China was built

★ In 2017, China's first crude lead continuous refining furnace with independent intellectual property rights was built

★ In 2019, China's first oxygen-enriched side top-blown furnace for processing lead matte was built

★ The first lead flash smelting furnace with independent intellectual property rights in China will be built in 2021

1. Oxygen-enriched side blowing furnace

The oxygen-enriched side-blown furnace is a modern nonferrous metallurgical molten pool smelting furnace innovatively developed by Changsha Nonferrous Metals Institute. It has been successfully used in copper, lead, antimony, tin, nickel, copper-based solid waste, waste circuit boards, lead-bismuth slag, zinc-containing waste residue, In the field of non-ferrous metals and waste residue treatment such as anode slime, a number of demonstration projects have been built and excellent results have been achieved. The size of oxygen-enriched side-blown furnace equipment ranges from 1 ㎡ to 70 ㎡, forming different series, obtaining more than 30 patent authorizations, and having completely independent intellectual property rights. Among them, "New Oxygen-enriched Side-Blowing Molten Pool Melting Technology" won the Innovation Award of China Patent Annual Conference.

Through continuous innovation and upgrading, oxygen-enriched side-blown furnaces have developed into mature furnace types with multiple series and specifications, including:

★ Oxygen-enriched side blowing copper/nickel smelting furnace

★ Oxygen-enriched side blowing lead oxidation/reduction furnace

★ Oxygen-enriched side blowing antimony/tin smelting furnace

★ Oxygen-enriched side-blowing laterite nickel ore smelting furnace

★ Oxygen-enriched side-blowing anode slime melting furnace

★ Oxygen-enriched side-blowing zinc leaching slag smelting furnace

★ Oxygen-enriched side-blowing solid waste/sludge smelting furnace

Popularization and application of oxygen-enriched side blowing furnace:

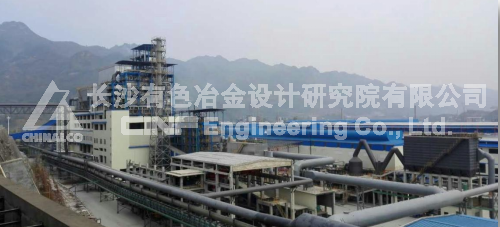

1. Xinjiang Kalatongke Copper-Nickel Mine Smelting Expansion Project

The world's first side-blown melting low-grade copper-nickel ore project

2. Chenzhou Fengyue High Arsenic Polymetallic Materials Comprehensive Recovery Project

The first integrated recycling project of lead-based polymetallic materials with double-side blowing treatment

Won the second prize of ministerial science and technology progress award in 2019

3. Southern Nonferrous Antimony Silver Polymetallic Comprehensive Recovery and Upgrading Project

The first "three-side blowing" (side blowing oxidation + side blowing reduction + side blowing fuming) lead-based complex metal direct lead smelting production line

Won the first prize of ministerial science and technology progress in 2019

4. Jingmen GEM Comprehensive Utilization Demonstration Project of Copper-containing Waste Residue and Sludge

The first side-blown treatment project of copper-containing sludge and solid waste

5. Qinghai Xianghe zinc smelting tailings harmless treatment and valuable metal comprehensive recovery project

The first side-blown treatment project of zinc-oxygen pressure leaching residue

6. Southern Nonferrous Leaching Slag Treatment System Upgrading Project

The world's largest side-blowing leaching residue treatment project

7. Nanguo Copper 400kt/a copper smelting process optimization and equipment upgrading project

World's largest side-blown copper smelting project

8. High matte nickel project of Jiaman New Energy Co., Ltd. (Indonesia will be put into production in 2025)

Worldwide pioneering project to produce nickel matte from laterite nickel mines by side blowing treatment

2. Lead flash smelting furnace

The lead flash smelting furnace is a metallurgical furnace introduced, digested, absorbed and re-innovated by Changsha Nonferrous Metals Institute to smelt lead concentrate and lead-containing materials to directly obtain crude lead. It has more than 20 related core patents and completely independent intellectual property rights. The unique feature of lead flash furnace is that it integrates oxidation and reduction processes in one metallurgical furnace. It is a short-process smelting equipment in the true sense. Flash smelting is used for oxidative desulfurization, coke filter layer is used for reduction smelting, and slag is clarified and separated in the electrode area, and some volatile metal oxides are fumed and volatilized. It is a large and complex metallurgical furnace integrating three metallurgical chemical processes: oxidation, reduction and fuming. Lead flash smelting furnace can process leaching slag or other lead-containing materials in zinc smelting enterprises at the same time. It is an advanced and environmentally friendly metallurgical furnace for developing circular economy and realizing the utilization of renewable resources in lead and zinc industry.

The green upgrading project of zinc smelting slag of CICC Lingnan Danxia Smelting Plant was put into operation in June 2022. It uses a flash lead smelting furnace to collaboratively process zinc smelting slag, social hazardous waste and other materials totaling nearly 300,000 tons/year, comprehensively recovering zinc, lead, copper, silver, cadmium, cobalt, sulfur and other valuable elements to achieve harmless treatment of smelting waste residue and comprehensive recycling of resources.

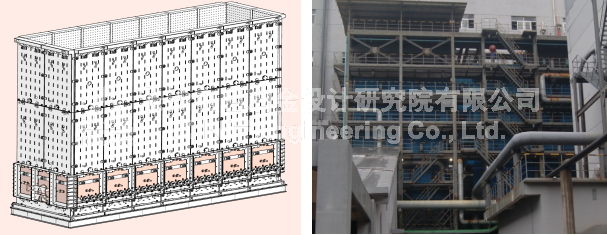

3. Fluidized roaster

Fluidized roaster (also known as boiling roaster) is one of the core equipment of zinc metallurgy production, and its calcine is the main raw material of most zinc smelting methods in the world. The development of roasters designed by Changsha Nonferrous Metals Institute has gone through the process of 4 ㎡, 5.4 ㎡, 8 ㎡, 16 ㎡, 18 ㎡, 38 ㎡, 42 ㎡, 60 ㎡, 80 ㎡, 110 ㎡, 119 ㎡, 153 ㎡, 198 ㎡, etc. Witnessed the development process of China's roasting furnace technology.

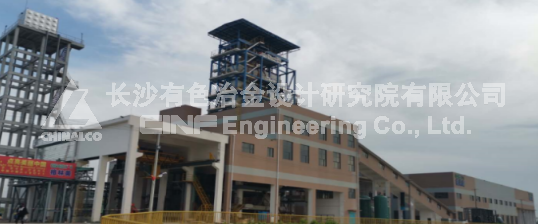

In recent years, Changsha Nonferrous Metals Institute has successively completed the engineering design of 110 ㎡, 119 ㎡, and 153 ㎡ boiling roasters, and developed and designed the world's largest hearth surface-a 198 ㎡ ultra-large boiling roaster (which has been put into production).

Southern Nonferrous 119 ㎡ Boiling Roaster

With the continuous increase of furnace area, the stability of furnace structure is becoming more and more difficult to control. Changsha Nonferrous Metals Institute has fully studied the feeding system, air supply system, flue gas system, furnace structure, refractory materials and other aspects of ultra-large fluidized roasting furnace, overcoming the core problems such as uneven material throwing, difficult air distribution, and large refractory expansion caused by large-scale equipment.

The 198m2 ultra-large boiling roaster can meet the smelting production requirements of 200,000 tons/year zinc metal, raising my country's zinc smelting technology and equipment manufacturing capabilities to a new height and becoming the world's leading smelting equipment.

Installation of the world's largest 198 ㎡ boiling roaster in Southern Nonferrous Metals

With the continuous increase of the single hearth area of zinc fluidized roaster, the raw material adaptability of fluidized roaster continues to improve, the unit capacity investment and comprehensive production cost continue to decrease, and the scale effect is highlighted. The large-scale fluidized roasting furnace will become an inevitable choice for large zinc smelting enterprises to improve their equipment level and market competitiveness in the future.

4. Fuming furnace

Fuming furnace is a pyrometallurgical smelting device that recovers volatile metals such as lead, zinc, tin, germanium and indium from non-ferrous metallurgical slag or refractory ore (such as low-grade tin oxide concentrate, low-grade lead-zinc oxide ore, etc.). It has the advantages of high metal volatilization rate, large processing capacity, relatively high mechanization degree and low energy consumption, and is one of the preferred metallurgical furnaces for all scale smelters to realize the development of circular economy.

The furnace area of the fuming furnace designed by Changsha Nonferrous Metals Institute is 3.9 ㎡, 5 ㎡, 7 ㎡, 8 ㎡, 12 ㎡, 18 ㎡, 48 ㎡, etc. It is widely used in the fuming treatment of lead, zinc, tin and other smelting slags.

Since the first 7 ㎡ fuming furnace designed for Zhuzhou Smelter was put into operation in 1986, after nearly 30 years of design, R&D and promotion, more than 30 fuming furnaces have been put into operation, more than 20 patents have been obtained, and the upgrading of the fuming furnace body, cooling system and waste heat recovery and utilization equipment has been continuously completed, supporting the innovation and development of the fuming process with the transformation and innovation of equipment structure, thus promoting the industrial upgrading of the whole smelting process.

In 1997, it independently developed and completed the first integrated device of waste heat boiler of fuming furnace in China, and obtained the national patent. In 1998, it was successfully applied in the first phase reconstruction project of Shaoye, which solved the technical problem that waste heat steam could not be continuously supplied due to the periodic operation of fuming furnace, and realized the comprehensive recovery of waste heat of fuming furnace.

In 2010, in the 100,000 t/a lead smelting project of Jiangxi Copper, the largest 18 ㎡ fuming furnace-waste heat boiler integrated device in China at that time was completed and put into operation. On the basis of meeting normal production, the initial success of continuous fuming operation was achieved; In 2014, in the Southern Nonferrous Three-Furnace Lead Smelting Project, an oxygen-enriched side-blowing continuous fuming furnace was developed and designed, and the process upgrade of fuming furnace equipment and production operations was realized, which is of great significance to the development of the entire industry.

The 12 ㎡ fuming furnace of Jiangxi Zili Resource Recycling Co., Ltd., which was designed and put into operation in 2015, realized the first waterless bottom fuming blowing production in tin smelting, providing valuable engineering practical experience for the diversification of fuming blowing equipment.

In 2018, when designing the "Hulunbuir Chihong Mining Co., Ltd. Oxygen Pressure Leaching Slag Resource Comprehensive Utilization Project", the newly developed pyrometallurgical furnace body upgrading patent developed by Changsha Nonferrous Metals Institute was applied to the fuming furnace, and an 18 ㎡ all-copper water jacket liquid molten pool fuming furnace was designed and built. It has achieved good economic and environmental benefits and has been highly recognized by the owner.

In 2021, in order to meet the requirements for large-scale upgrading of lead and zinc smelting projects, in the "Nandan County Nanfang Nonferrous Metals Co., Ltd. Leaching Slag Treatment System Upgrading Project", a 48-square-meter smoke blowing furnace with the largest hearth area in the world was designed. The furnace has been put into operation recently, fully considering the stability and safety issues in the process of large-scale furnaces and providing core equipment support for lead and zinc smelting enterprises to achieve large-scale benefits.

Southern Nonferrous 48 ㎡ fuming blowing furnace

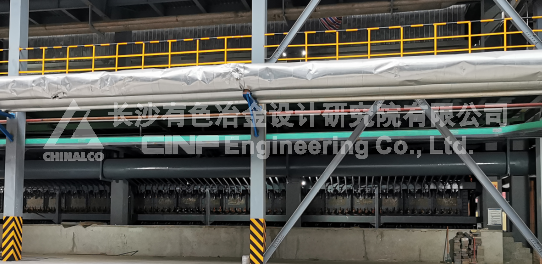

5. Crude lead continuous refining furnace

Crude lead continuous refining furnace is an environmentally friendly metallurgical furnace independently developed for the purpose of realizing crude lead continuous refining. Crude lead continuous refining technology is a unique technology of Changsha Nonferrous Metals Institute in China. It uses the technical principle of melting copper removal and sulfidation copper removal. By changing the mass transfer and heat transfer mode of traditional crude lead fire refining process, a top-down temperature gradient is formed in the melt layer in the furnace. This technology won the first prize of Science and Technology Progress Award of China Nonferrous Metals Industry Association.

Crude lead continuous refining process and continuous refining furnace realize the transformation of lead crude pyrometallurgical refining process from high pollution and high labor intensity to environmentally friendly and automatic production.

The crude lead continuous refining furnace has the following characteristics:

1) One step of the crude lead continuous refining furnace replaces the traditional two steps of removing copper in the lead melting pot and treating copper scum in the scum reverberatory furnace, which has short process flow, energy saving and consumption reduction;

2) Continuous refining of crude lead has high copper removal rate and good quality of lead anode plate;

3) Realize the continuous operation of crude lead pyrometallurgical refining. The matte and slag are in a molten state in the furnace and can automatically flow out without manual slag removal, reducing labor and labor intensity, and greatly improving the operating environment;

4) The continuous crude lead refining matte product has low lead content, low copper grade and high matte value;

5) The hot crude lead is directly fed into the continuous refining furnace, making full use of the latent heat of the lead liquid and saving fuel.

In recent years, Changsha Nonferrous Metals Institute has provided crude lead continuous refining technology and refining furnaces for

Southern Nonferrous Metals, Yuguang Gold and Lead, and Danxia smelters.

Yuguang gold and lead 20 ㎡ crude lead continuous refining furnace

CICC Lingnan Danxia Smelter 13 ㎡ crude lead continuous refining furnace

6. Multi-stage roasting oven

A multi-stage roasting furnace that can adapt to multi-property materials. It consists of a furnace body, driving device, central shaft, furnace rake, temperature control system, etc. It can continuously roast materials at up to 1000 °C, accurately control the roasting time and temperature of materials, and can adapt to the roasting of cohesive materials, and can be used in material roasting and impurity removal (such as zinc oxide roasting and defluorination and chlorination) and other fields.

CICC Lingnan Danxia Smelting Plant 10th floor 220 ㎡ multi-stage roaster

Previous Page

Previous Page

Next Page

Related Product Recommendation

Exhaust gas scrubbing equipment

Electrolysis multi functional automatic overhead crane

Automatic zinc stripping machine

online message