Chemical Technology

In the field of chemical industry, the company has been committed to the development and application of non-ferrous metal-related chemical projects such as salt lake lithium extraction, ore lithium extraction, comprehensive recovery of waste batteries and waste residue resources, clean vanadium extraction, flue gas acid production, flue gas treatment, and proprietary equipment, etc., with "new process for selective and efficient extraction and separation of lithium products from salt lake brine", "lepidolite salt replacement lithium extraction and comprehensive utilization technology", "gas separation pre-conversion high concentrationSO2 A number of technological achievements represented by "flue gas acid production technology" have reached the domestic leading level, and a number of classic benchmark projects have been successfully created.

Keywords: production equipment selection, system manufacturing, upgrading

Classification:

Engineering case

messages

Product Description

In the field of chemical industry, the company has been committed to the development and application of non-ferrous metal-related chemical projects such as salt lake lithium extraction, ore lithium extraction, comprehensive recovery of waste batteries and waste residue resources, clean vanadium extraction, flue gas acid production, flue gas treatment, and proprietary equipment, etc., with "new process for selective and efficient extraction and separation of lithium products from salt lake brine", "lepidolite salt replacement lithium extraction and comprehensive utilization technology", "gas separation pre-conversion high concentrationSO2 A number of technological achievements represented by "flue gas acid production technology" have reached the domestic leading level, and a number of classic benchmark projects have been successfully created.

1. Lithium extraction from salt lakes

1.1 Qinghai Lithium Industry Co., Ltd. 's annual output of 10,000 tons/year battery-grade lithium carbonate project

The use of ion selective electromigration technology to separate magnesium and lithium has achieved breakthrough development in salt lake lithium extraction technology. The project won the first prize for outstanding engineering design achievements of China Nonferrous Metals Construction Association in 2013 and the first prize of Qinghai Provincial Science and Technology Award in 2012.

1.2 Qinghai Jinwei New Material Technology Co., Ltd. 's annual output of 6,000 tons of high-purity lithium carbonate construction project

It adopts adsorption + membrane separation and concentration + electrodialysis boron removal + MVR evaporation + lithium precipitation process, which is a representative project in China using aluminum-based adsorption + membrane technology.

1.3Argentina SDLA Salt Lake Lithium Chloride Technical Transformation and Upgrading Project with an Annual Production of 2,500 Tons (LCE)

Saturated lithium chloride brine (lithium concentration ~ 60 g/L) was refined by lithium chloride by full membrane method, evaporated and crystallized to obtain lithium chloride products.

1.4 Qinghai Dongtai Jinaier Salt Lake Lithium, Potassium and Boron Mineral Resources Development and Utilization Project (Phase II)

The project scale produces 10,000 tons of lithium carbonate per year. It uses ion selective migration and separation technology to treat old salt lake brine (containing 0.5% lithium). It was successfully put into production in one go in 2018. The product meets the quality requirements of battery-grade lithium carbonate and won the 2021 China Nonferrous Metals Construction Association First Prize for Excellent Engineering Design Achievements.

1.5 Comprehensive utilization project of boron and lithium resources in Baqiancuo Salt Lake, Geji County, Tibet Autonomous Region

The world's highest (4,900 meters) lithium carbonate plant, with a project scale of 10,000 tons of lithium carbonate per year, will be partially put into operation in 2023.

1.6 Lithium extraction construction project with an annual output of 25,000 tons (LCE) in Uyuni Salt Lake, Bolivia

The factory adopts the process route of brine filtration + brine preheating + electrochemical adsorption + refining and impurity removal + evaporation and concentration + lithium precipitation to produce battery-grade lithium carbonate, which is the first raw brine lithium extraction project in the world's largest salt lake.

2. Lithium extraction from ore

2.1 Jiangxi Yongxing Special Steel New Energy Technology Co., Ltd. annual output of 30,000 t battery-grade lithium carbonate project (Phase I + Phase II)

The first domestic industrial project to produce battery-grade lithium carbonate from low-grade high-fluorine lepidolite marks the beginning of large-scale development of lithium extraction from lepidolite in China and is of symbolic significance in the industry. Won the first prize for outstanding design achievements of China Nonferrous Metals Construction Association in 2024.

2.2 Yifeng Times New Energy Materials Co., Ltd. annual output of 40,000 tons of battery-grade lithium carbonate project

The process of "salt roasting, decomposition and replacement to extract battery-grade lithium carbonate" was used to treat lepidolite (grade 1.5% Li2O), and it was successfully put into production in October 2023. It is equipped with 2 tunnel kiln production lines (3.98 W × 216. 72 L) and 4 rotary kiln production lines (φ 4.88 × 70), which is the largest scale of lepidolite production of lithium carbonate monomer.

2.3 Fengxin Times New Energy Materials Co., Ltd. Lithium Battery Materials Project

The first phase has an annual output of 30,000 tons of battery-grade lithium carbonate and will be successfully put into production in September 2023. Two rotary kilns are used to treat lepidolite (grade 1.5% Li2O), and a single rotary kiln is used to roast (φ5200mm × 110m). The roasted clinker is leached, solid-liquid separation, continuous impurity removal, purification and lithium precipitation to obtain the finished product lithium carbonate.

2.4 Jiangxi Lingneng Lithium Industry Co., Ltd. annual output of 20,000 tons of lithium iron phosphate production line construction project

The first phase of the 10,000 tons/year battery-grade lithium carbonate project has been put into operation in July 2022. The project adopts the tunnel kiln roasting process to meet the owner's progress requirements. It only took 8 months from the beginning of the project design to the production of lithium carbonate.

2.5 Yifeng County Jinfeng Lithium Industry Co., Ltd. annual output of 30,000 tons of battery-grade lithium carbonate project

The process of "salt roasting, decomposition, replacement and extraction of battery-grade lithium carbonate" is adopted to process lepidolite (grade 2%-3% Li2O). It is equipped with a tunnel kiln production line-a roller kiln production line. It will be successfully put into operation in July 2023.

2.6 Dawei Co., Ltd. Chenzhou Guiyang battery-grade lithium carbonate project with an annual output of 40,000 tons

The process of "salt method + acid method roasting, decomposition, replacement and extraction of battery-grade lithium carbonate" is adopted to treat lepidolite (grade 1.8% Li2O). The first phase of the project is equipped with two rotary kiln production lines (φ 4.8 × 90 m) and is expected to be put into operation in 2025.

3. Resource recovery

3.1 Shunhua Lithium Industry Co., Ltd. processing 150,000 t/a waste power batteries and waste recycling project

The construction scale of the first phase is to recycle a total of 50,000 tons of lithium iron phosphate battery waste per year, with an annual output of 5,000 tons of battery-grade lithium carbonate. The project adopts "selective priority lithium extraction technology", with short process flow, high lithium extraction efficiency and low production cost. It is a leading demonstration project for the recycling of waste lithium iron phosphate batteries in China.

3.2 Longbai Lufeng Titanium Industry Co., Ltd. 's 300,000 tons/year high calcium magnesium titanium slag deep impurity removal and upgrading large-scale boiling chlorination raw material project

Adopting the "atmospheric pressure leaching + hydrochloric acid pressure leaching" process, it can process 300,000 tons of high-calcium magnesium titanium slag annually, providing high-quality raw materials for the chloride titanium dioxide production line. It is the country's first hydrochloric acid pressure leaching process to treat titanium slag.

3.3 Jiangxi Barton Environmental Protection Technology Co., Ltd. Polymetal Comprehensive Recycling Project

The mixed acid pressure leaching process of hydrochloric acid + sulfuric acid is used to process multi-metal recycled waste containing copper, tin, nickel and other metals, with an annual processing capacity of 120,000 tons of materials. This process is the first of its kind in China and was successfully put into operation in September 2023. The equipment operation rate is high and the metal leaching rate is high, creating huge economic benefits for owners.

4. Clean vanadium extraction

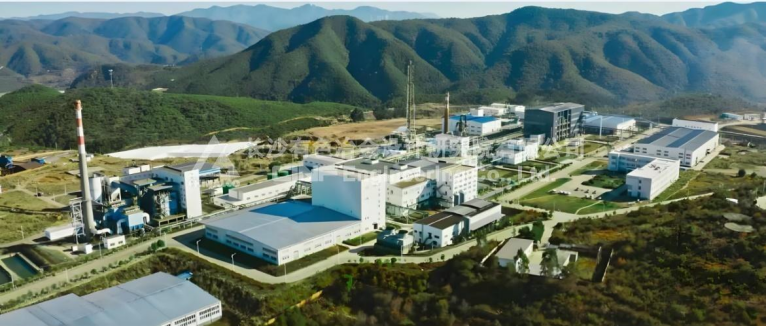

4.1 50,000 tons/year vanadium slag sub-molten salt method for efficient vanadium extraction and clean production demonstration project

It was put into operation in June, 2017. It adopts the sub-molten salt method to clean vanadium extraction process, which eliminates wastewater and waste gas emissions from the source, and realizes resource utilization of vanadium extraction tailings. The vanadium extraction efficiency is high and the production cost is low, representing the green development direction of vanadium and titanium industry in China.

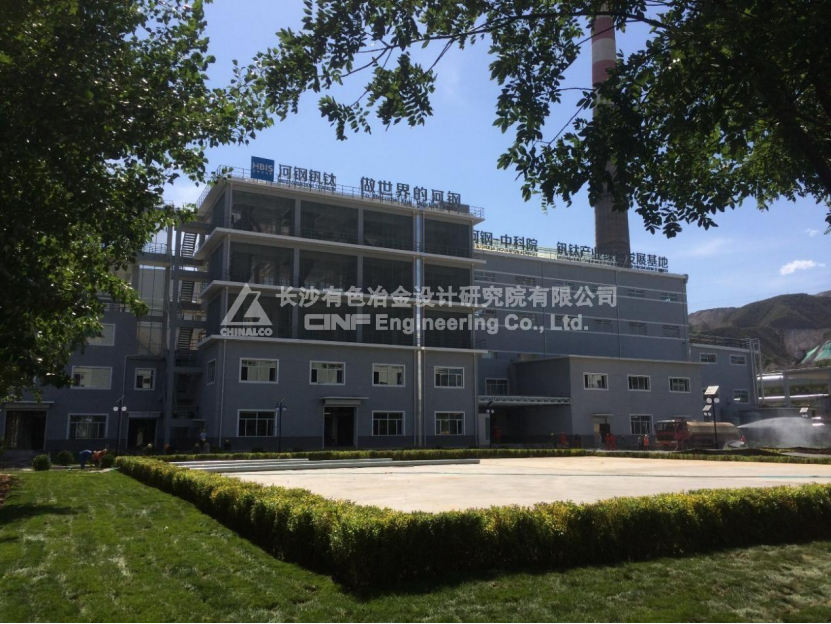

4.2 Chengde Vanadium and Titanium New Materials Co., Ltd. Vanadium and Titanium Industrial Park Project

The main construction contents of the vanadium and titanium park of Chengde Vanadium and Titanium New Materials Co., Ltd. cover high-purity vanadium, aviation sheet vanadium, aviation-grade vanadium aluminum alloy, waste denitrification catalyst recovery, vanadium electrolyte, etc. Changsha Nonferrous Metals Institute is responsible for the entire stage of work from park planning, engineering consulting to design. As of October 2024, high-purity vanadium, aviation sheet vanadium, vanadium aluminum alloy and vanadium electrolyte projects have been completed and put into production.

4.3 Annual output of 150,000 m3 energy storage core new material-all-vanadium redox flow battery electrolyte project

In the first phase, it will process 500,000 tons of vanadium-titanium magnetite imported from South Africa annually, produce 40,000 m3 of all-vanadium redox flow battery electrolyte annually, and produce titanium-rich fine powder and iron-rich fine powder. The project adopts the vanadium extraction process of “calcification roasting + oxalic acid leaching” to directly extract vanadium from vanadium-titanium magnetite, and the vanadium extraction tailings adopt “reduction roasting + magnetic separation” to separate titanium and iron, so as to realize the recovery of all components of vanadium-titanium magnetite.

5. Flue gas acid production

5.1 Nandan County Nanfang Nonferrous Metals Co., Ltd. 198 flat boiling roasting supporting acid production system project

The project is equipped with a 198-level boiling roaster with an acid production capacity of 400,000 t/a. It adopts the two-rotation and two-suction acid production process. The purification system adopts the patented technology of sewage acid reduction, which greatly reduces the discharge of sewage acid.

5.2 Hulun Buir Chihong Mining Acid Production System Technology Upgrade Project

It adopts the two-rotation and two-suction acid production process, with an annual output of 200,000 tons of 98% sulfuric acid. It adopts our company's patented deep mercury removal technology. The quality of sulfuric acid products is better than the requirements of high-quality industrial sulfuric acid products. The project will be put into operation in 2020. Won the second prize of Outstanding Engineering Design Achievement Award of China Nonferrous Metals Construction Association in 2021.

5.3 Qinghai Xiyu Nonferrous Metals Co., Ltd. Polymetallic Resources Comprehensive Recycling and Environmental Protection Upgrading Project

Smelting flue gas is used to produce acid with an annual output of 340,000 tons of sulfuric acid/a (including: 98% sulfuric acid 260kt/a and 104.5% sulfuric acid 80kt/a). The project will be put into operation in October 2024.

5.4 Southern non-ferrous leaching residue treatment supporting fluctuating high-concentration acid production project

It adopts the patented technology of high-concentration SO2 flue gas separation and pre-conversion to produce sulfuric acid to process complex mixed gases. The dry suction process is equipped with a low-temperature heat recovery system. The conversion process is equipped with medium and low pressure boilers. The 98% industrial sulfuric acid scale is 330,000 tons/year-460,000 tons/year, which is a model of flue gas fluctuation type high-concentration SO2 flue gas acid production project.

5.5 Chuxiong Dianzhong Nonferrous 430ka/t Sulfuric Acid Project

The project adopts pre-conversion, pre-absorption and 3 +1 conversion processes to ensure that the conversion rate is as high as 99.95%, and enables the exhaust gas SO2 and acid mist to meet special emission requirements. Won the second prize of Outstanding Engineering Design Achievement Award of China Nonferrous Metals Construction Association in 2020.

5.6 Guangxi Nandan Nanfang Antimony-Silver System Cold Shock Pre-conversion High Concentration Acid Production Project

It was put into operation in 2019 and adopts patented cold shock pre-conversion technology with a design scale of 300,000 tons/year. It has made a breakthrough in solving the problem that the SO2 concentration of flue gas treated by the two-rotation and two-suction process cannot exceed 12%.

5.7 Xinling Lead Industry's polymetallic comprehensive utilization smelting flue gas acid production system

The project adopts the "3 +2" double conversion + hydrogen peroxide desulfurization process, with an annual output of 300,000 tons of 98% sulfuric acid, and will be put into operation in 2023.

5.8 Zhongze Jitie WSA Wet Acidification Project

For the first time in China, the WSA wet acid process is used to treat molybdenum smelting and roasting flue gas. The SO2 concentration of the flue gas is about 2% to 3%, and 30,000 tons of 97% concentrated sulfuric acid is produced per year. It will be put into operation in 2023. Won the second prize of Outstanding Engineering Design Achievement Award of China Nonferrous Metals Construction Association in 2023.

6. Flue gas treatment

6.1 Baiyin copper smelting flue gas purification project

The project uses ionic liquid desulfurization technology to treat 480,000 Nm3/h ring collection flue gas and 240,000 Nm3/h sulfuric acid tail gas. The ultra-large nickel-based alloy lined combined desulfurization tower adopts a diameter of 9.8 meters (95 meters high) and a diameter of 6.8 meters (100 meters high). The self-supporting chimney integrated combined tower is the largest and tallest integrated combined tower for smelting flue gas desulfurization in China.

6.2 Zinc oxide desulfurization project of antimony-silver system in southern Guangxi

Adopting the company's new patented ultra-clean flue gas emission treatment technology, the zinc oxide smoke produced by the system is used as raw material to treat the flue gas of the fuming furnace, and it will be put into operation in 2020.

6.3 Development Project of Mercury-Containing Flue Gas in Guizhou Gravity Technology Mercury Smelter

Adsorption mercury removal technology is used to deeply purify the exhaust gas, and the process flow is simple, and the mercury resources can be recovered and utilized to the maximum extent.

Previous Page

Next Page

Previous Page

Next Page

Related Product Recommendation

Exhaust gas scrubbing equipment

Electrolysis multi functional automatic overhead crane

Automatic zinc stripping machine

online message