Mining Engineering

Mining Engineering

Keywords: production equipment selection, system manufacturing, upgrading

Classification:

Engineering case

messages

Product Description

1. Project

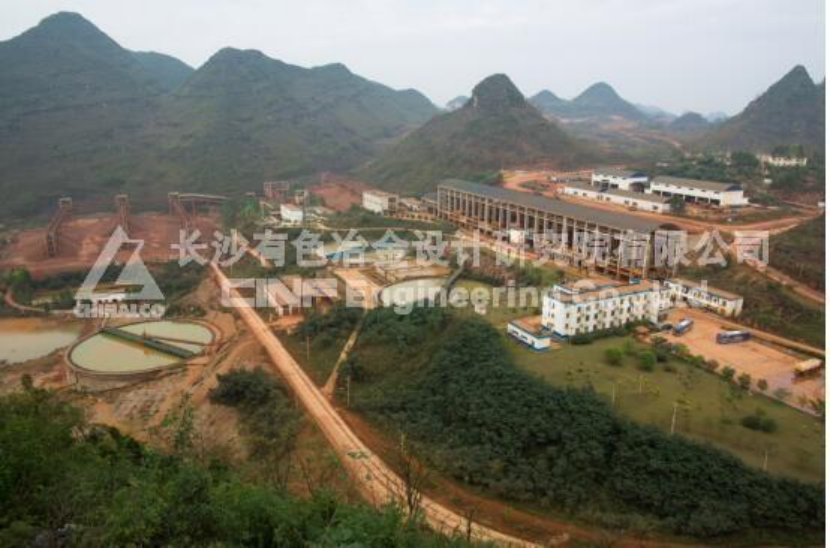

8800 kt/a open-pit mining project of Pingguo bauxite mine of Chinalco Guangxi Branch

Project status

It is the first time in the world to develop and utilize karst accumulation bauxite deposits, pioneer ultra-large karst accumulation bauxite mining and engineering reclamation technology, fill the gap in the world, and is at the international leading level.

Awards

The first, second and third phases of Pingguo Aluminum projects have successively won the Ministerial Science and Technology Special Contribution Award, the second prize of the National Science and Technology Progress Award, the National Excellent Engineering Design Gold Award, and the National Quality Engineering Silver Award. They are the "National Green Mine Pilot Unit", The first batch of "Demonstration Base for Comprehensive Utilization of Mineral Resources" and "National Advanced Environmental Protection Unit".

2. Project

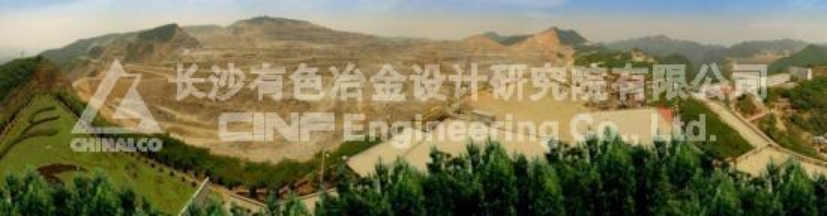

Mining and dressing project of Sandaozhuang molybdenum mine in Luanchuan, Henan

Project status

Sandaozhuang molybdenum mine started from 5,000 t/d, and through multiple expansion designs, the production scale has reached 50,000 t/d, making it the largest molybdenum mine in China. The technology of open-pit deep-hole high-step blasting to treat extra-large goaf, the column-machine combined beneficiation process of large flotation column + 130 cubic meter self-suction flotation machine, and the technology of high-concentration long-distance transportation of tailings are at the leading level in China, and are the first batch of "demonstration bases for comprehensive utilization of mineral resources" in China.

Awards

Won the first prize of ministerial-level excellent engineering design and the silver prize of national excellent engineering design.

3. Project

Henan Luanchuan Longyu Molybdenum Industry Nannihu Molybdenum Mine Mining and Processing Project

Project status

At that time, it was the largest mining and dressing project completed and put into production in the domestic molybdenum industry at one time, and the current production scale is 30,000 t/d. Open-pit stope adopts multiple entrance and exit ditches to achieve the shortest transportation distance of ore and rock. The concentrate adopts a new environmentally friendly and energy-saving technology of filter press + electromagnetic drying, and the tailings pond adopts a new technology of small cycle energy-saving dam.

Awards

Won the first prize of ministerial-level excellent engineering design

4. Project

Mongolia xindu Mining Co., Ltd. Tumultin Aobao Zinc Mine

Project status

Mongolia's alpine mines have achieved remarkable economic, environmental and social benefits after they were put into operation, and are a model of Sino-Mongolian cooperation.

Awards

Won the National Silver Award for Excellent Engineering Design and the Luban Award for China Construction Engineering (Overseas Project).

5. Project

Inner Mongolia Zhongxi Mining Co., Ltd. Dasuji Molybdenum Mine Mining and Processing Project

Project status

The designed mining and dressing production scale is 10,000 t/d, the tailings are dehydrated by belt filter, the filter cake is dry piled on site, and all the filtrates are returned to the beneficiation plant for recycling.

6. Project

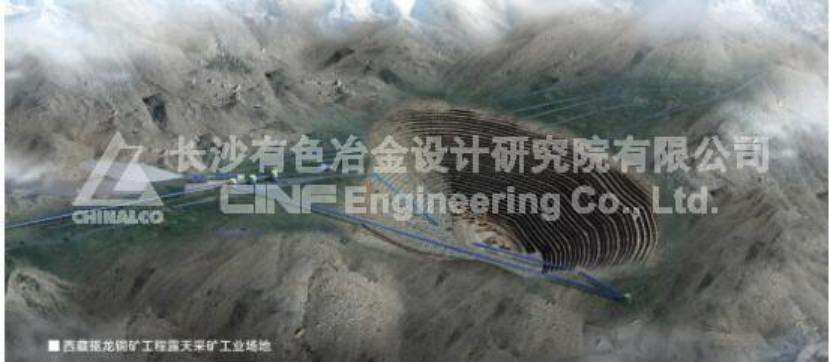

Qulong Copper Mine Project in Tibet

Project status

Qulong Copper Mine in Tibet, the highest altitude in the world, is the largest open-pit copper mine in China, with a designed mining and dressing capacity of 45,000 kt/a. This project is a mine with advanced production technology and equipment and the highest level of intelligence at home and abroad.

7. Project

CICC Lingnan Nonferrous Metals Co., Ltd. Fankou Lead-Zinc Mine

Project status

Fankou lead-zinc mine has a mining and dressing scale of 1800Kt/a and an annual output of 180,000 tons of lead and zinc metal. It is the largest lead-zinc mining and dressing production base in Asia. Mine water prevention and control, intelligent remote control equipment bottomless retreat large-aperture mining, high-performance foam mortar paste filling and full tailings filling, deep well filling and decompression, ground pressure microseismic surveillance, high alkali potential regulation priority flotation, wastewater Comprehensive utilization and other technologies have the world's advanced level.

Awards

Won the National Excellent Engineering Design Gold Award and many national, provincial and ministerial scientific and technological progress awards.

8. Project

Huaxi Group Tongkeng Tin Mine Mining and Dressing Project and Gaofeng Tin Mine Mining Project

Project status

Guangxi Dachang Tin Base of Huaxi Group is the largest tin polymetallic manufacturer in Asia. The production scale of Tongkeng tin mine in the main mine is 2000kt/a, and the supporting mining technology of underground large-scale fully trackless equipment, cementation filling of block mortar and crushed stone cement slurry, underground fire prevention and extinguishing, heavy medium pre-selection and coarse-grained jigging and waste disposal, long-distance cableway transportation and fine mud cassiterite flotation technology have reached the world advanced level. The main mine, Gaofeng Tin Mine, is a rare tin-rich polymetallic mine in the world.

Awards

Won the National Excellent Engineering Design Bronze Award and many provincial and ministerial scientific and technological progress awards.

9. Project

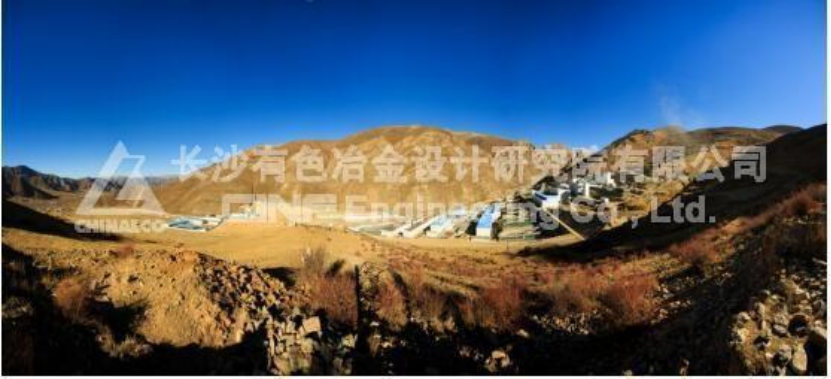

Phase I mining and dressing project of Jiama copper polymetallic mine in Tibet

Project status

Jiama copper polymetallic mine is located in the Tibetan Plateau, with an ore body elevation of 4000-5407m and a mining and dressing scale of 2000kt/a in the first phase. The design adopts world-class mining and dressing technology to overcome many worldwide technical problems in plateau mines. In 2010, China's first internationally advanced plateau modern mine was built. At the 2011 National Qinghai-Tibet Special Work Conference, the completion and commissioning of the first phase mining and dressing project of Jiama copper polymetallic mine and the remarkable economic, environmental and social benefits were highly praised.

Awards

Won the first prize of ministerial-level excellent engineering design

10. Project

Hubei Sanxin Gold and Copper Co., Ltd. Mining and Processing Project

Project status

Jiguanzui Taohuazui Gold Mine of Hubei Sanxin Gold and Copper Co., Ltd. is a large skarn-type polymetallic deposit of gold, copper, sulfur and iron, buried under Daye Lake, with a designed production scale of 1000 kt/a. The vertical sand silo feng-shui linkage high-concentration pulping technology, high-concentration full tailings cementation filling technology, surface and underground water prevention technology are at the leading level in China.

Awards

Won the first prize of ministerial-level excellent engineering design.

11. Project

Hunan Shizhuyuan tungsten-molybdenum polymetallic ore mining and dressing project

Project status

Shizhuyuan polymetallic mine is praised as the "World Nonferrous Metals Museum" by Chinese and foreign geologists. The first new comprehensive beneficiation technology of tungsten-molybdenum-bismuth complex polymetallic ore, named "Persimmon Bamboo Garden Method", this technology fills the gap in the world and is at the international leading level.

Awards

Won the second prize of National Science and Technology Progress Award and the silver prize of National Excellent Engineering Design

12. Project

Jinchuan Group Co., Ltd. Longshou Mine 3000kt/a capacity expansion underground mining project

Project status

Longshou Mine is one of the super-large copper-nickel sulfide deposits under Jinchuan Group Co., Ltd., with a designed underground mining production scale of 3000kt/a. Under the engineering geological conditions of crushed ore and rock, extremely poor stability, and high in-situ stress, my country's first over-1,000-meter mixed well was built. The design adopted shaft support technology, downward hexagonal approach cementation filling mining technology and gravel mortar cementation filling technology are at the leading level in China.

13. Project

2000t/d beneficiation project of Shaanxi Jianchaling Nickel Industry Co., Ltd

Project status

Sino-Australian cooperative mine. It is a large-scale low-grade nickel deposit in China. It adopts SAB crushing technology and column machine combined separation process to successfully solve the beneficiation problem of refractory nickel ore with high mud content, and has the leading level in China.

Previous Page

Next Page

Previous Page

Next Page

Related Product Recommendation

Exhaust gas scrubbing equipment

Electrolysis multi functional automatic overhead crane

Automatic zinc stripping machine

online message