Smelting engineering

Smelting engineering

Keywords: production equipment selection, system manufacturing, upgrading

Classification:

Engineering case

messages

Product Description

1. Project

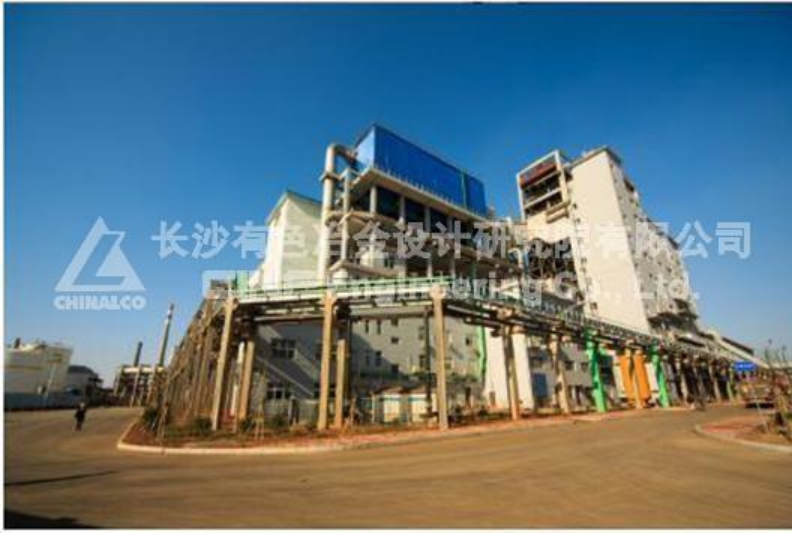

200kt/a lead-zinc smelting and resource comprehensive utilization project of Jiangxi Copper Group Company

Project status

The project is designed to produce 100,000 tons of electric zinc and 100,000 tons of electric leadannually. Zinc smelting adopts conventional hydrometallurgical zinc smelting process, 110 square meters large boiling roasting furnace, large cathode plate and automatic zinc stripping technology; Lead smelting adopts Kivcet direct lead smelting process and large anode plate vertical mold casting technology, and combined production of lead and zinc to realize comprehensive utilization of resources and development of circular economy. The project was successfully put into production in March 2012.

Awards

Won the first prize of Ministerial Excellent Engineering Consulting Achievements in 2009 and the second prize of National Excellent Engineering Consulting Achievements in 2009.

2. Project

Zhuzhou Metallurgical Group Co., Ltd. direct lead smelting project with zinc leaching residue kivcet

Project status

Our company introduced Kivcet's direct lead smelting technology for the first time, and treated the leaching residue produced by the zinc smelting system of Zhuzhou Metallurgical Group. It is designed to produce 120,000 tons of electric lead per year. The joint production of lead and zinc will improve the overall smelting level of the enterprise and contribute to the development of circular economy. The project was successfully put into production in January 2013.

Awards

Won the first prize of Outstanding Engineering Consulting Achievements of China Nonferrous Metals Construction Association in 2006 and the first prize of Outstanding EngineeringConsulting Achievements of Hunan Province in 2009.

3. Project

environmental protection treatment project

Project status

For the first time in my country, the "liquid high-lead slag direct reduction technology" of lead smelting was applied to industrial production, and the oxygen-enriched bottom-blowing oxidation + oxygen-enriched bottom-blowing reduction process was used for large-scale production of crude lead, which solved the key technical problems such as high energy consumption and poor environmental protection in the reduction process of SKS process blast furnace.

Awards

"Research and Industrial Application of Liquid High Lead Slag Direct Reduction Technology" won the first prize of China Nonferrous Metals Industry Science and Technology Award in 2011; "Key Technologies and Industrialization of Efficient and Clean Metallurgy and Resource Recycling of Lead" won the second prize of National Science and Technology Progress Award of the People's Republic of China in 2012.

4. Project

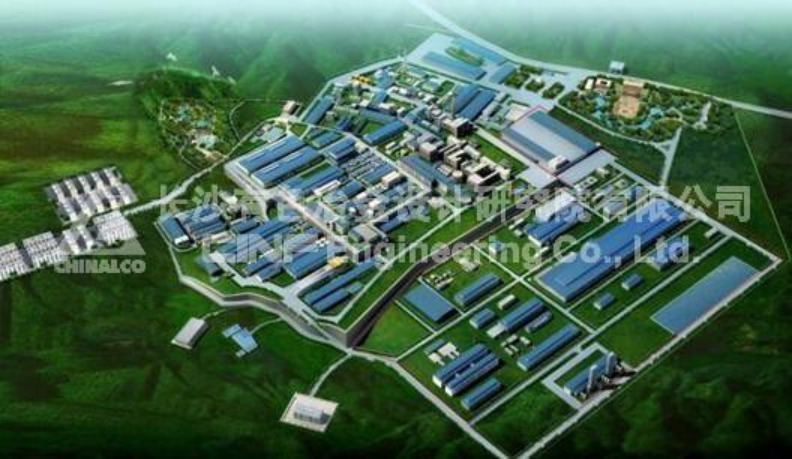

Hechi Nanfang Nonferrous Smelting Co., Ltd. Lead-Zinc Joint Smelting Circular Economy Environmental Governance Industrial Upgrading Project

Project status

Adopt our company's independently developed oxygen-enriched side-blown pool melting crude lead continuous smelting technology (CSCCPb) to treat lead-containing mixture of lead concentrate, lead-antimony ore and part of zinc leaching slag, and continuously produce crude lead through oxygen-enriched side-blown furnace oxidation smelting oxygen-enriched side-blown furnace reduction smelting fuming furnace continuous blowing; Electric lead is produced by anode vertical mold casting and automatic conveying line. The design scale of the project is to produce 100,000 tons of electric lead per year.

5. Project

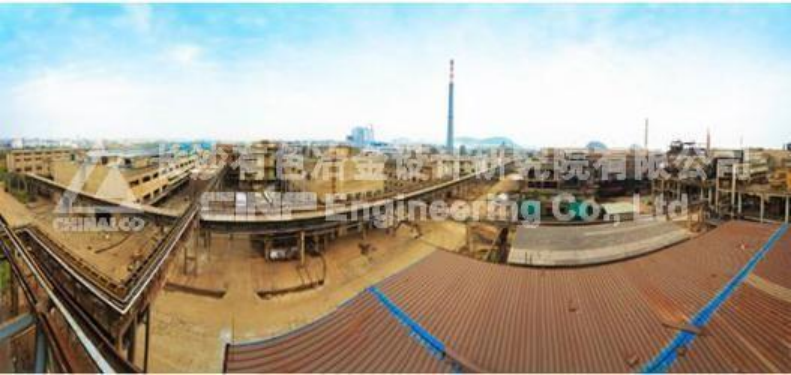

Technical transformation project of comprehensive recovery of gallium and germanium by 100kt/a zinc oxygen pressure leaching technology in Danxia Smelter of Zhongjin Lingnan

Project status

Our company introduced the pressurized oxygen hydrometallurgy zinc smelting technology for the first time, and built the first large-scale zinc oxygen pressure leaching process production line in China through general contracting. It adopted large cathode plates and automatic zinc stripping technology for the first time, and realized the clean production and sulfur recovery of zinc smelting for the first time, while efficiently recovering gallium, germanium and other valuable metals. Environmental protection, energy conservation and comprehensive technical indicators have reached the advanced level of the same industry in the world. The project was commissioned in September 2009.

Awards

Won the first prize of Ministerial Excellent Engineering Design Award of China Nonferrous Metals Construction Association in 2011; First Prize of Science and Technology of China Nonferrous Metals Industry Association in 2012.

6. Project

New technology project of 100kt/a electro-zinc oxygen pressure leaching of Western Mining Co., Ltd

Project status

The design scale of the project is to produce 100kt of electro-zinc per year. The core process introduces oxygen pressure leaching hydrometallurgical zinc smelting technology. The electrowinning uses large cathode plates and automatic zinc stripping technology, and recovers sulfur through flotation to achieve fully wet clean production of zinc smelting. This project is the second zinc smelting project in my country to apply zinc oxygen pressure leaching and sulfur recovery processes on a large scale after Zhongjin Lingnan Danxia Smelter.

7. Project

Laibin Huaxi Smelting Co., Ltd. Indium Zinc System Energy Saving and Emission Reduction Comprehensive Utilization Transformation Project

Project status

The original 55kt/a zinc-indium smelting system was reformed by using zinc calcine thermal acid reduction leaching of hematite iron removal process, which realized the expansion of production and consumption, energy saving and emission reduction, greatly improved the recovery rate of indium and recovered valuable metals as much as possible. The design scale of the project is to produce 100,000 tons of electric zinc per year.

Awards

The process design of indium system in Laibin Smelter won the first prize of Engineering Design Innovation Award of China Nonferrous Metals Construction Association in 2001.

8. Project

Renovation Project of 100kt/a Zinc Boiling Roasting and Supporting Acid Production System of Hechi Nanfang Nonferrous Smelting Co., Ltd

Project status

The project uses a 119m2 boiling furnace to produce calcined sand, with a designed scale of 100,000 tons/year zinc metal. It is matched with the company's built 200kt/a electric zinc production line. The by-product sulfur dioxide flue gas is utilized by waste heat to produce sulfuric acid. The project was completed and put into operation in 2009.

9. Project

Xinjiang Xinxin Mining Co., Ltd. Kalatongke Copper-Nickel Mine Smelting Expansion Project

Project status

This project is the first time that my country has applied self-developed oxygen-enriched side-blown molten pool smelting technology (CSC) to complex refractory copper-nickel mixed ore. Through equipment and technology upgrades, it has greatly improved the smelting production efficiency of copper-nickel mixed ore, improved environmental protection and operating conditions, and achieved energy conservation, emission reduction and efficient and comprehensive recovery of valuable metals. The design scale of the project is high nickel matte with an annual output of 8,000 tons of nickel metal, and it was put into production in December 2010. Oxygen-enriched side-blown molten pool smelting technology (CSC) has been included in the national key energy-saving technology promotion catalogue by the National Development and Reform Commission.

Awards

The oxygen side-blown molten pool smelting and direct lead smelting technology won the 2006 Hunan Provincial Excellent Technology Innovation Project Award and the 2011 Fifth China Patent Annual Conference Innovation Award.

10. Project

Zhuzhou Cemented Carbide Group Co., Ltd. Old System Technical Transformation Project

Fine tungsten carbide engineering

Technical transformation project of tungsten and molybdenum system deep processing

Technical transformation project of tantalum powder and tantalum wire production line

Technical transformation project of traditional mixture production line

Technical transformation project of cobalt powder production line

Technical transformation project of PC bar and mixture production line

Project status

Through the introduction, digestion and absorption, the technical transformation project of the old system of cemented carbide powder, mixture, alloy and large products has improved the technical content of products and adjusted the product structure, demonstrating its technological leading position in the domestic cemented carbide production industry.

Awards

The old system technical transformation project won the 9th National Silver Award for Excellent Engineering Design

Fine tungsten carbide project won the second prize of ministerial-level excellent engineering design

Second Prize of Provincial Excellent Survey and Design of Tungsten and Molybdenum System Deep Processing Technical Transformation Project

First Prize of Ministerial-level Excellent Engineering Design for Technical Transformation Project of Traditional Mixture Production Line

11. Project

Technical Transformation Project of Cemented Carbide System (Introduction) of Zigong Cemented Carbide Co., Ltd

Project status

The system has introduced internationally advanced paraffin technology and advanced cemented carbide grades from developed countries in Europe and America, such as P10, P35, K10, K30, M15, M30 and other internationally advanced levels, and achieved leap-forward development in technical level.

Awards

The technical transformation project of cemented carbide system (introduction) won the silver award of national excellent engineering design

Molybdenum wire production line introduction engineering process design won the second prize of ministerial-level professional and technological innovation award

The technical transformation project of the mixture preparation center of Zigong Cemented Carbide Co., Ltd. won the third prize of national outstanding engineering consulting achievements

12. Project

Technical transformation project of tungsten powder and tungsten carbide production line of Nanchang Cemented Carbide Co., Ltd

Project status

The project introduces international advanced mixing and carbon blending equipment and technology, and tungsten powder hydrogen reduction technology to produce ultrafine tungsten powder and tungsten carbide. The successful application of core technologies such as tungsten mixing and carbon blending demonstrates its leading advantage in the domestic tungsten and cemented carbide production industry.

13. Project

Guangxi Huiyuan Manganese Industry 30,000 t/a high purity low selenium electrolytic manganese metal and 20,000 t/a mercury-free alkali manganese electrolytic manganese dioxide project

Project status

The main process of the project adopts the two-mine one-step method, and the design scale is to produce 30,000 t/a high-purity low-selenium electrolytic manganese metal and 20,000 t/a mercury-free alkaline manganese electrolytic manganese dioxide annually. The project was successfully put into production in December 2006. The main production indicators all reached or exceeded the design indicators, and the overall equipment and technology ranked among the leading domestic and international advanced levels.

Awards

Won the first prize of ministerial-level excellent engineering design in the national nonferrous metal industry in 2010

14. Project

Guizhou Wuling Manganese Industry Co., Ltd. Tongren Area (Songtao) Manganese Series Products Deep Processing and Supporting Project (Phase I) Project

Project status

This project is currently the largest electrolytic manganese metal project under construction in my country.

15. Project

Jinchuan Group Co., Ltd. 4000t/a cobalt product capacity expansion and consumption reduction technical transformation project

Project status

This project is a key project for Jinchuan Group to build the first aircraft carrier in the nickel-cobalt industry. The design capacity is to produce 4,000 tons of cobalt products per year. The design adopts the main process of leaching, extraction, cobalt precipitation and spray drying. In the year of production, all indicators met the standards. The project design adopts an all-steel structure standard factory building, which opens a precedent for the application of steel structure factories in heavy-duty anti-corrosion areas of my country's nonferrous smelting industry.

Awards

Won the first prize of 2005 Excellent Engineering Design Award of China Nonferrous Metals Construction Association, the 2006 National Quality Engineering Silver Award, and the 12th National Excellent Engineering Design Silver Award.

16. Project

Qinghai Dongtai Jinaier Salt Lake Lithium, Potassium and Boron Mineral Resources Development and Utilization Project (Phase II)

Project status

The project is transformed on the basis of the original scale of 3,000 t/a lithium carbonate (Phase I), and the scale of the second phase will reach an annual output of 10,000 tons of high-purity industrial-grade lithium carbonate. The project adopts the world's advanced magnesium-lithium separation technology to achieve the economical production of high-purity industrial-grade lithium carbonate from salt lake brine with high magnesium-lithium ratio.

Awards

This project won the first prize of Qinghai Science and Technology Award in 2011.

Previous Page

Next Page

Previous Page

Next Page

Related Product Recommendation

Exhaust gas scrubbing equipment

Electrolysis multi functional automatic overhead crane

Automatic zinc stripping machine

online message